COB Strip single color

Key Specifications

Voltage: 12V/24V | CHIPS: 256/264/288/300/480 CHIPs | Cut Points: 3.14CM CUT/1.1CM CUT | WIDTH: 5MM/8MM/10MM

Product Details

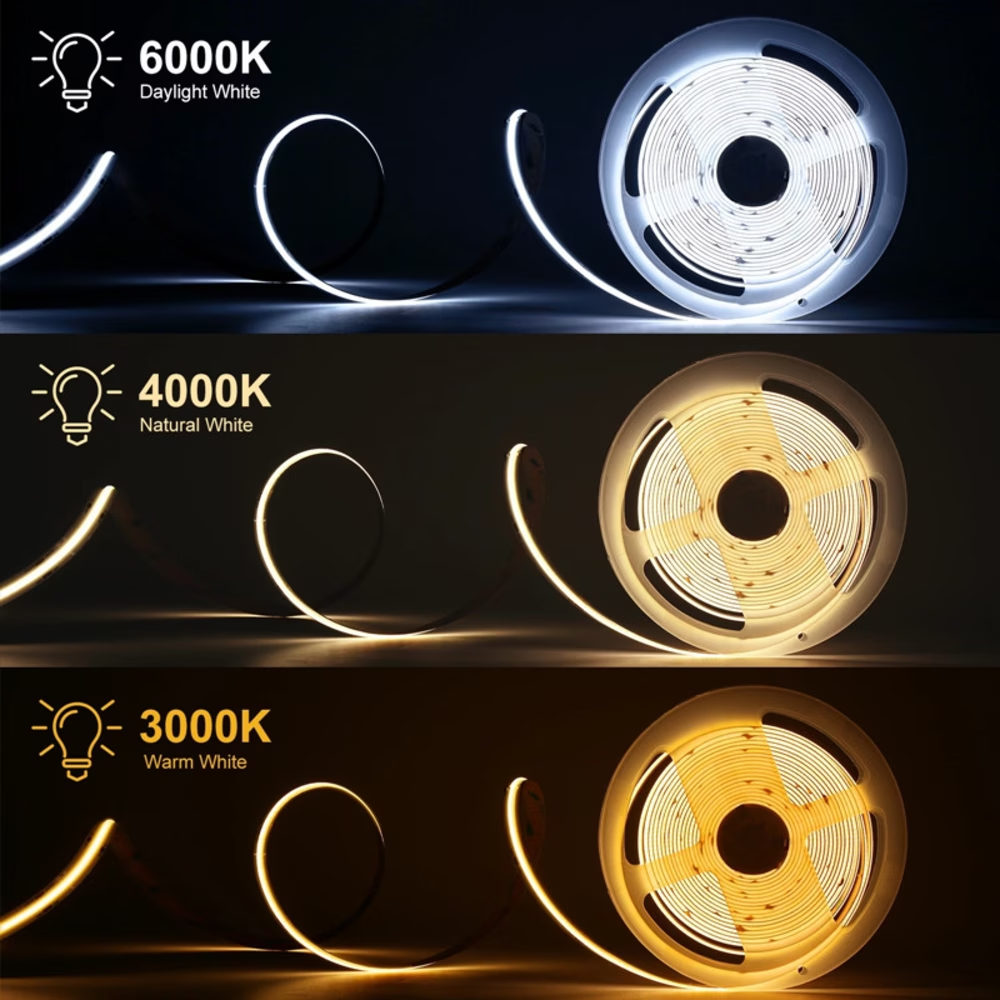

Color Options

Product Description

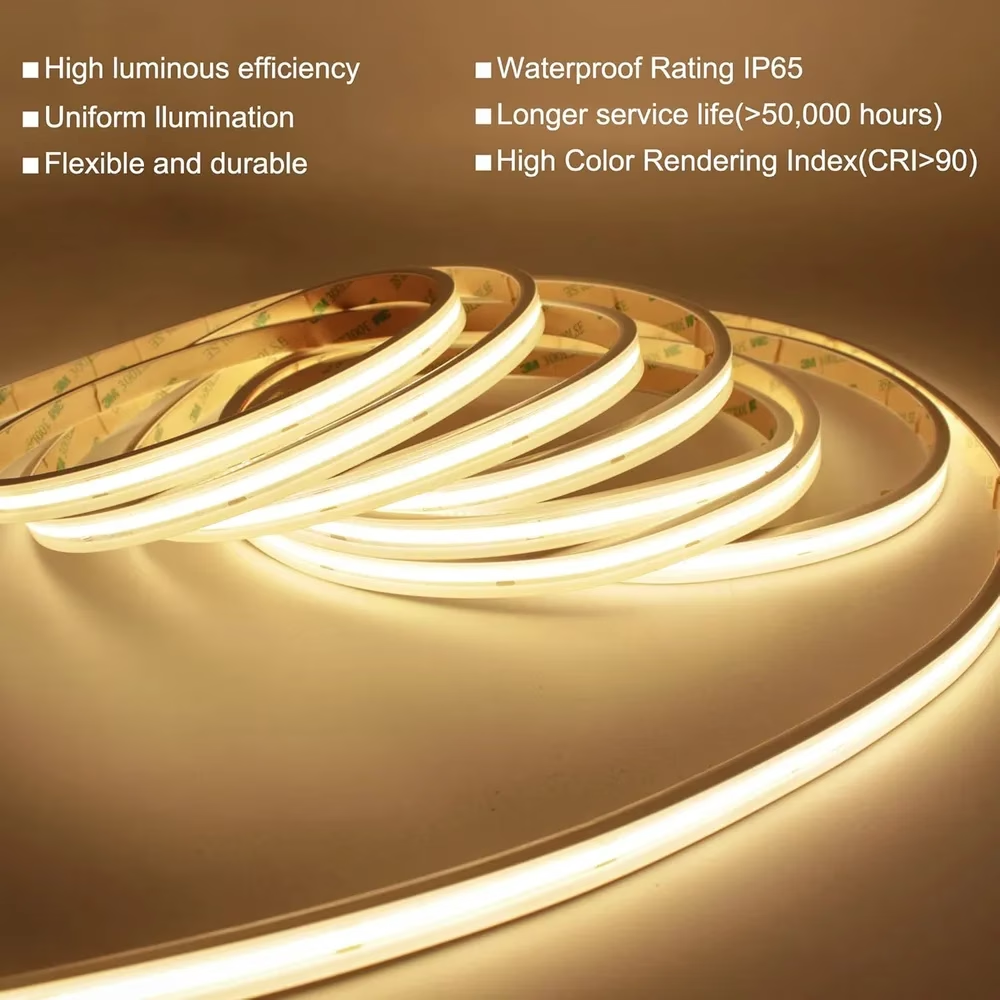

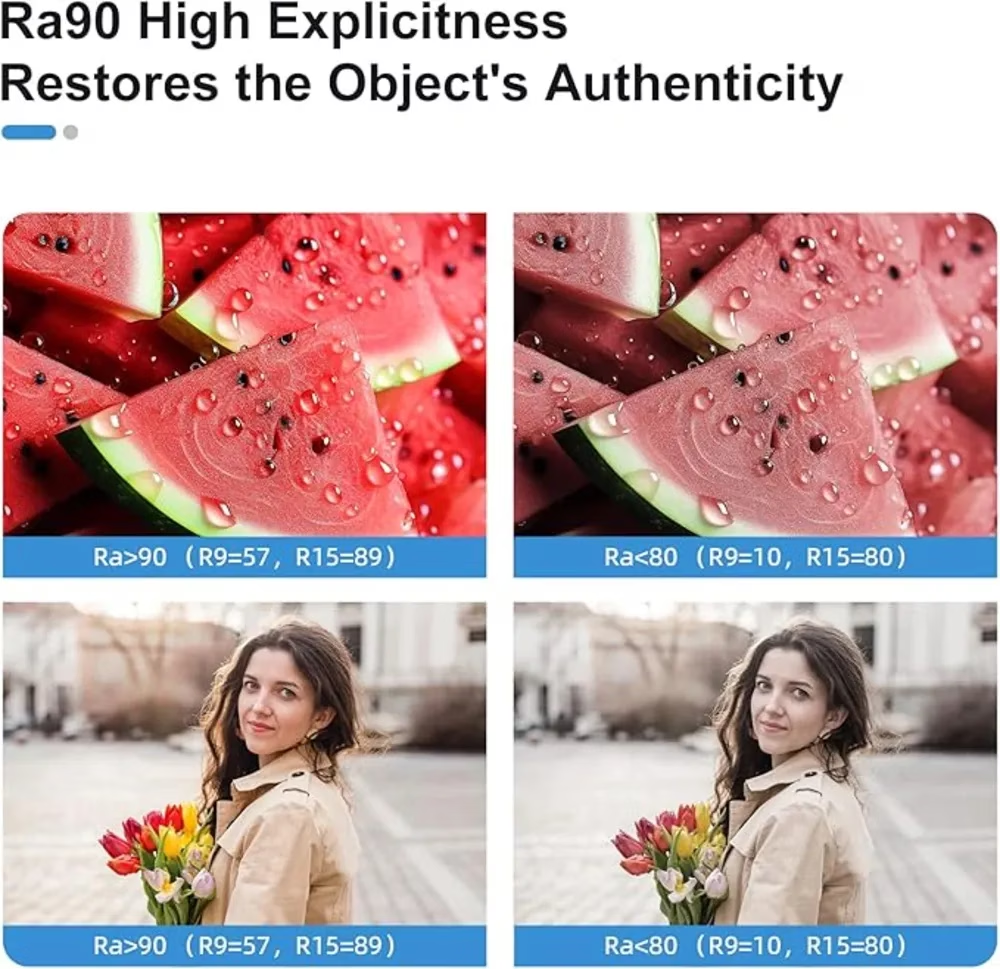

product features:

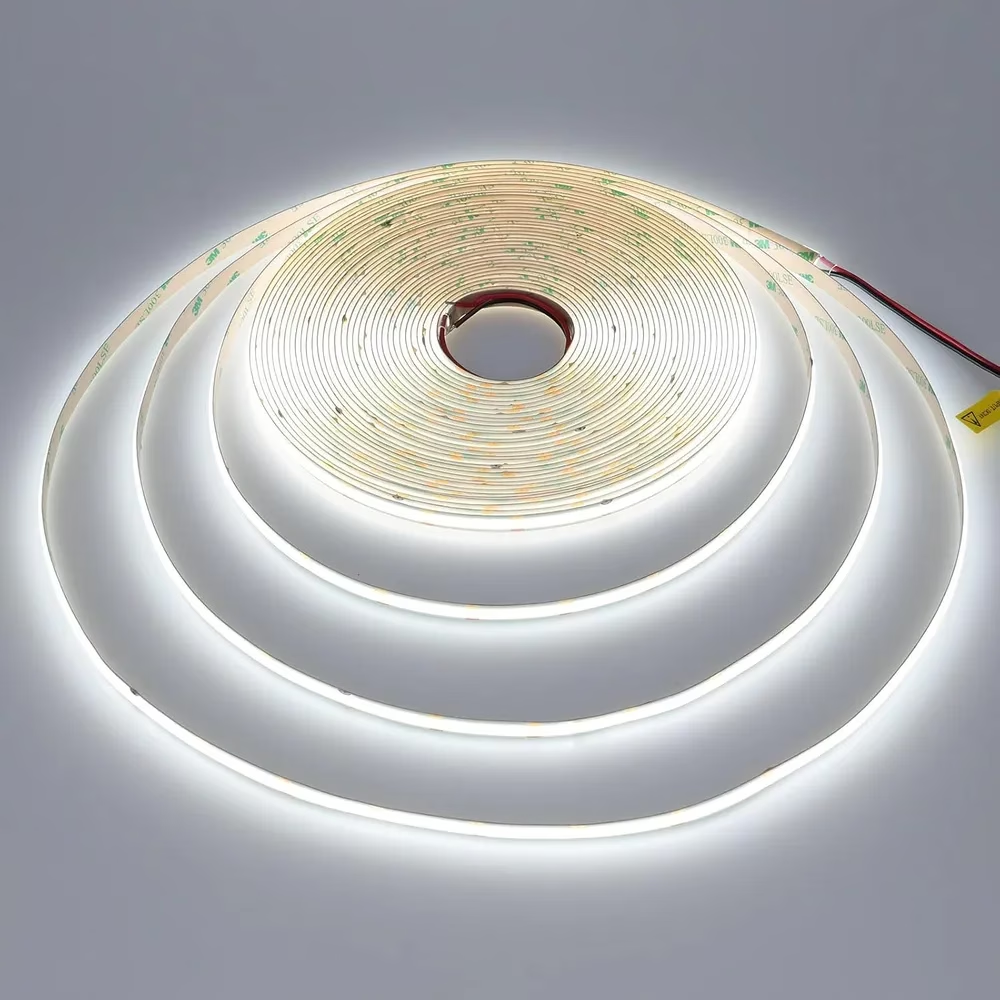

1.High brightness, slight drop, no light spot, no shadow, light soft and cozy;

2.The largest light beam Angle is 180 °;

3.The Antistatic grade is (MIL-STD-883E): HBM 2 (2000~4000V);

4.Suitable for flexible lamp installation method, No harmful substances, comply with RoHS environmental protection standard;

5.The top choice for ambient lighting and mood - enhancing illumination

6. Driven by low - voltage DC (Direct Current), powered with safe voltage, ensuring reliable and secure operation

7.Capable of being cut and extended at the scissor - mouth position of each unit

Application:

1.It is typically installed for decorative purposes in companies and homes, on floors, ceilings, furniture, and as hidden - channel backlight sources.

2.It enjoys a wide - ranging application in hotels, hostels, entertainment venues, exhibitions, exhibition halls, various festive events, and stage settings. For instance, it can be used for step lighting, booth lighting, corridor lighting, staircase lighting, and lighting in concealed areas. The color selection can be tailored according to the specific application scenarios.

3.Ideal for shopping mall decorative lighting, it can be installed in showcases, wine cabinets, shoe cabinets, ceilings, hidden compartments, wardrobes, and jewelry counters.

4.Applicable to contour - shaping applications for billboards, signboards, and logos

5.Characterized by its elegance and stunning beauty, it has recently been extensively applied in architectural decorations, decorative lighting fixtures with unique shapes, and a variety of outdoor decorative lamps

MODELS AND PARAMETERS:

| MODEL NO. | VOLT. | SIZE/MM | CCT/K | LM/M | CHIPS/PCS | POWER/W | PCB UM | RA | CM/CUT | IP |

| 256D-80RA-2700K-5M | 12V/24V | 8*5000 | 2700K | ≥120 | 256 | 10 | 25/35 | ≥80 | 3.14 | IP20 |

| 256D-80RA-3000K-5M | 12V/24V | 8*5000 | 3000K | ≥120 | 256 | 10 | 25/35 | ≥80 | 3.14 | IP20 |

| 256D-80RA-3500K-5M | 12V/24V | 8*5000 | 3500K | ≥120 | 256 | 10 | 25/35 | ≥80 | 3.14 | IP20 |

| 256D-80RA-4000K-5M | 12V/24V | 8*5000 | 4000K | ≥120 | 256 | 10 | 25/35 | ≥80 | 3.14 | IP20 |

| 256D-80RA-5000K-5M | 12V/24V | 8*5000 | 5000K | ≥120 | 256 | 10 | 25/35 | ≥80 | 3.14 | IP20 |

| 256D-80RA-6000K-5M | 12V/24V | 8*5000 | 6000K | ≥120 | 256 | 10 | 25/35 | ≥80 | 3.14 | IP20 |

| 256D-10000K-5M | 12V/24V | 8*5000 | 10000K | ≥110 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

| 256D-RED-5M | 12V/24V | 8*5000 | 620-625nm | ≥25 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

| 256D-GREEN-5M | 12V/24V | 8*5000 | 520-530nm | ≥70 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

| 256D-BLUE-5M | 12V/24V | 8*5000 | 460-470nm | ≥20 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

| 256D-YELLOW-5M | 12V/24V | 8*5000 | 587-590nm | ≥120 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

| 256D-PINK-5M | 12V/24V | 8*5000 | PINK | ≥40 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

| 256D-ICE BLUE-5M | 12V/24V | 8*5000 | 480-470nm | ≥80 | 256 | 10 | 25/35 | / | 3.14 | IP20 |

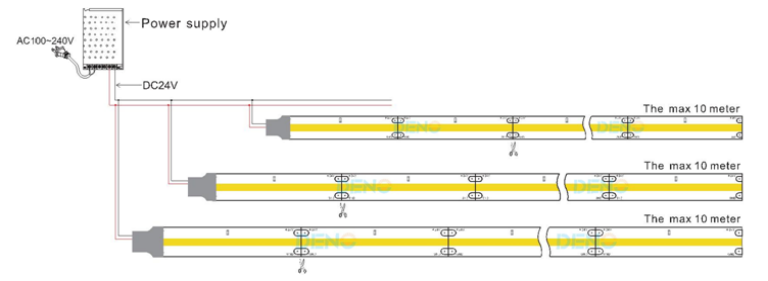

Installation diagram:

1.A single connection

2.Multiple connection

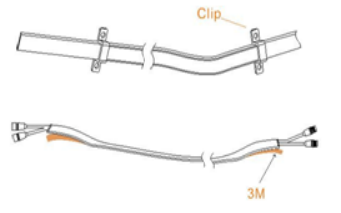

Lamp fixing method

1. Using 3M glue

2.Using silicon clip and screws to fix;

3.Fixing in the slot;

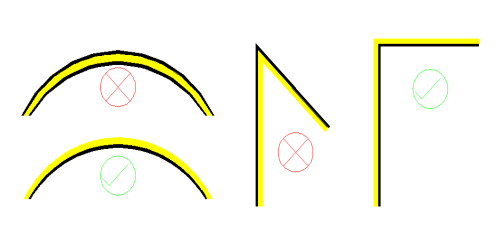

Bending diagram:

WARM REMINDING:

Avoid exposing the light - emitting area of the COB LED strip lights to sharp or hard objects. Do not drag the LED lights on the ground to prevent scratches or damage to the protective layer.

Keep the light - emitting area of the strip lights away from high - temperature objects directly. The instant surface temperature of the light - emitting area should be below 210℃.

Do not twist the product over short distances. For a single 0.5 - meter strip light, the maximum twisting angle is 720°, and the bending diameter at any position should be greater than 1cm.

Choose the switching power supply size according to the actual number of connected strip lights and reserve a 20% margin to avoid power supply damage.

When connecting the device, do not damage the connecting wires on the circuit board.

Pay attention to electrical standards when powering on the LED strip lights. Ensure correct voltage and connect the positive and negative poles strictly as required to prevent LED damage.

The waterproof glue on the LED light surface is corrosive. If the waterproofing is corroded or damaged due to the contractor's mistakes during installation, it is not covered by the warranty.